zbfloor@cnzbsports.com

+8617363073605 +8617332761215

Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

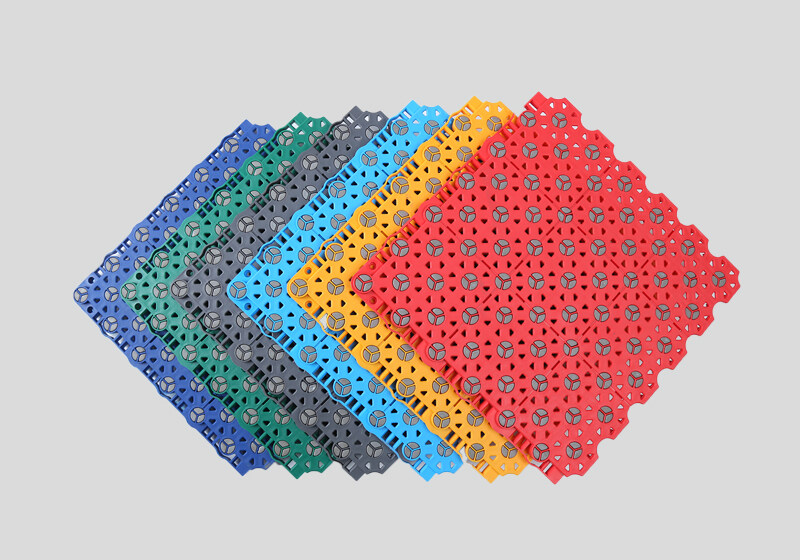

Suspended floors are used in various places, and the parameters you need can be set according to your needs.

Such as thickness, material, required size, pattern, color, resistance, coefficient of friction, etc. These are

parameters. The following is an analysis of the details. First of all, the frictional resistance of the suspended floor is between 0.5-0.7. The friction resistance of the

suspended floor used as a ground decoration raw material in sports competitions is 0.5-0.7. The tested assembled

floor samples were placed in a 70-degree high-temperature box for 24 hours. The test standard stipulates that there

will be no melting, cracking, or obvious color cast after 24 hours. Secondly, the suspended floor has no cracks and no obvious color cast for 24 hours at an ultra-low temperature of

minus 40 degrees Celsius. Put the assembled sample floor into the freezer for 24 hours, the temperature is set at

-40 degrees. Afterwards, check the floor for cracks. No noticeable color cast. Floors are easy to assemble. The assembled floor should be able to withstand a symmetrical

stress of 15KN for 1 minute without damage. Flooring shall pass xylene and total volatile emissions tests and meet

requirements. Because the requirement of appearance quality is that the color of the floor is symmetrical and consistent, without

obvious color cast; the surface of the suspended floor has no cracks, bubbles, poor melting, and the surface of

the suspended assembled floor has no burrs. Therefore, the rebound rate of the suspended assembled floor to the

ball is 90%. According to the technical test standard of basketball court rebound, the suspended floor can meet

the requirements of basketball court.